O Ring Running Friction

Metals such as copper brass or aluminum can be rapidly worn away by a moving o ring this is especially true if high pressures are involved.

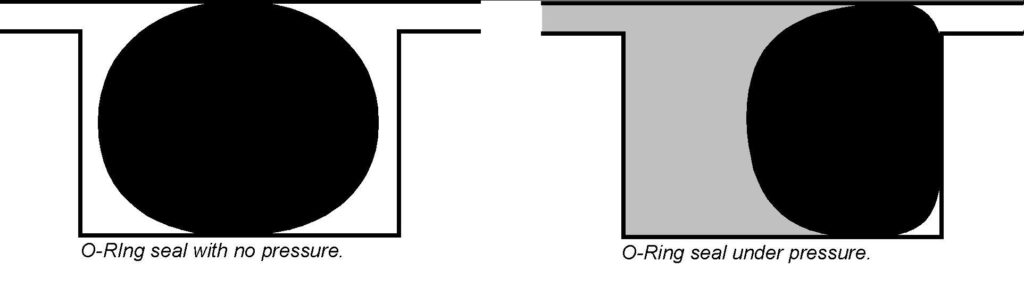

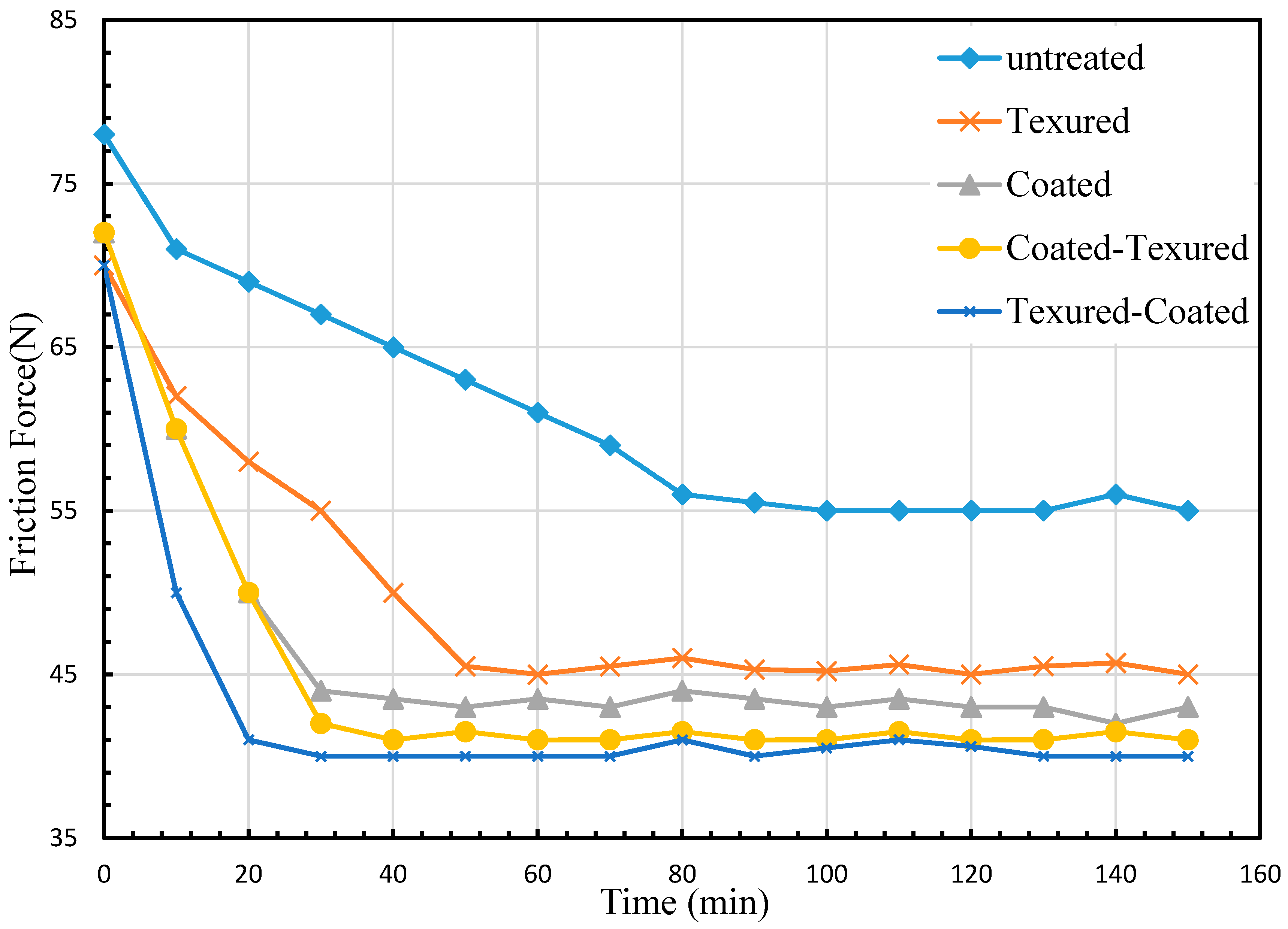

O ring running friction. Since this can easily be forgotten it is preferable to provide a vent hole between the two o rings. The improvement in break out friction with a chlorinated o ring or seal is negligible but a chlorinated o ring can be used in combination with external. Hardness of the rubber type of surface surface finish squeeze on the o ring amount and type of lubrication fluid pressure temperature the amount of break out friction that a system will generate depends on the length of time the surfaces of the metal and the seal element have been in physical contact at rest. If unexplained leakage occurs with these or other soft metals it is good practice to check the metal dimensions for.

In addition to the usual causes of running friction. This is especially true if high pressures are involved. Chlorination is a permanent process that can be applied to existing stock o rings or seals to provide a much smoother seal surface with reduced running friction in dynamic applications. High running friction may cause difficulty by wearing soft metal parts.

The axial friction maximum friction stress and maximum contact stress of the o ring are analysed using finite element method as the confining pressure varying from 50 to 300 kpa. Metals such as copper brass aluminum can be rapidly worn away by a moving o ring.