O Ring Breakout Friction

Although a harder compound will in general have a lower coefficient of friction than a softer material the actual running and breakout friction values are actually higher because the compressive load required to achieve the proper squeeze and force the harder material into a given o ring cavity is so much greater.

O ring breakout friction. The parker o ring handbook is a hardcover manual. In addition to the usual causes of running friction. An o ring also known as a packing or a toric joint is a mechanical gasket in the shape of a torus. This is often called breakout friction or its breakout point.

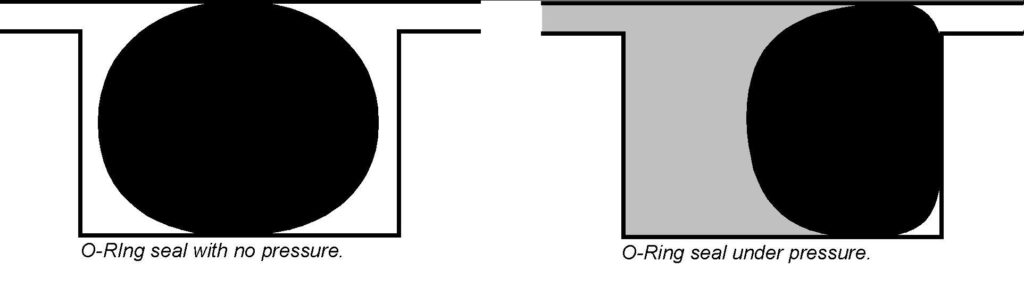

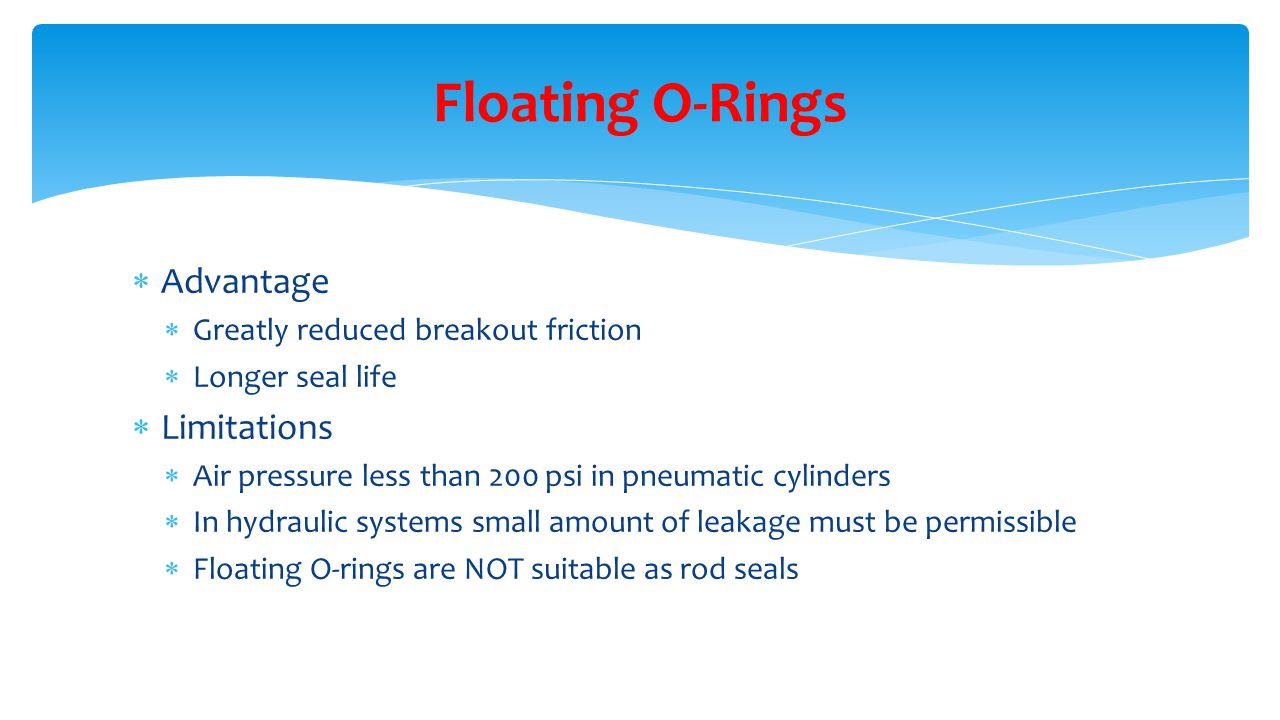

This pressure can tear portions of the seal that adhered to the gland wall causing seal failure. Running friction is lower than breakout friction. Break out friction in addition to the usual causes of friction such as the hardness of the rubber the type of surface the surface finish the squeeze on the o ring the amount and type of iubrication and the fluid pressure and temperature the amount of break out friction which an o ring will develop depends. The torsional resistance of the o ring also resists twisting.

Breakout friction is the force necessary to start relative motion. The o ring may be used in static applications or in dynamic applications where there is relative motion between. However the actual running and breakout friction values of a harder compound with lower coefficients of friction are higher because the load required to squeeze the harder material into the o ring groove is much greater. Because static friction is opposing the force you are applying to the o ring.

The frictional force is stronger than the force you are applying to the o ring preventing it from sliding. O rings tend not to roll in normal operation because fluid pressure forces a larger area of the o ring against the gland than against the shaft. The o ring causing friction and heat. The softer the elastomer the more risk that at high operating pressure the elastomer of the o ring will extrude into the.

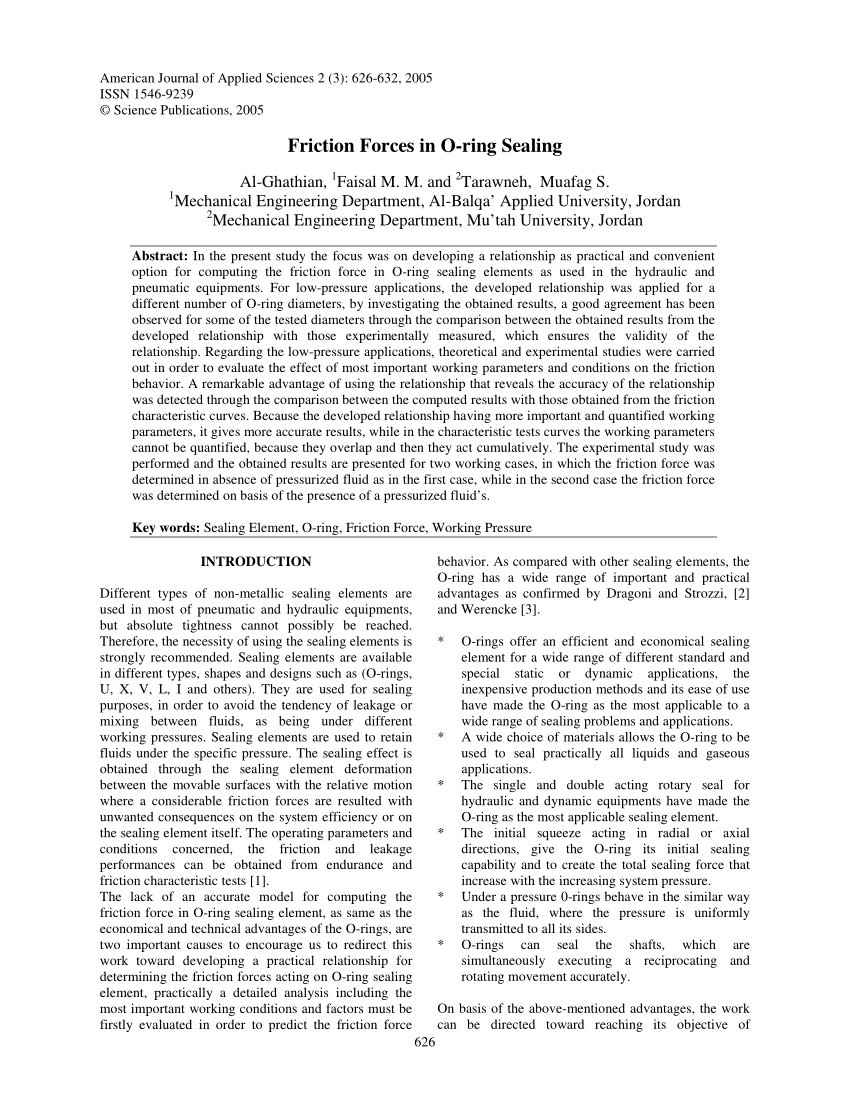

It is a loop of elastomer with a round cross section designed to be seated in a groove and compressed during assembly between two or more parts creating a seal at the interface. Hardness of the rubber type of surface surface finish squeeze on the o ring amount and type of lubrication fluid pressure temperature the amount of break out friction that a system will generate depends on the length of time the surfaces of the metal and the seal element have been in physical contact at rest. Effects of breakout friction can cause excessively high pressures to develop. To minimize or reduce wear the.

Limiting friction is the friction acting on an object just before it begins to move. This is depen dent upon the length of the time between cycles. Because rubber is a poor conductor of heat the o ring can loose its proper ties. In continuously moving applications excessive o ring running friction can cause heat to build up within the o ring material itself.